Vegetable Oils like Soya, Sunflower, Cottonseeds, Rapeseeds etc. are first subject to the process of Degumming. Here Phosphotites in the Oil are hydrated with water and then removed by separating in the Centrifugal Separators.

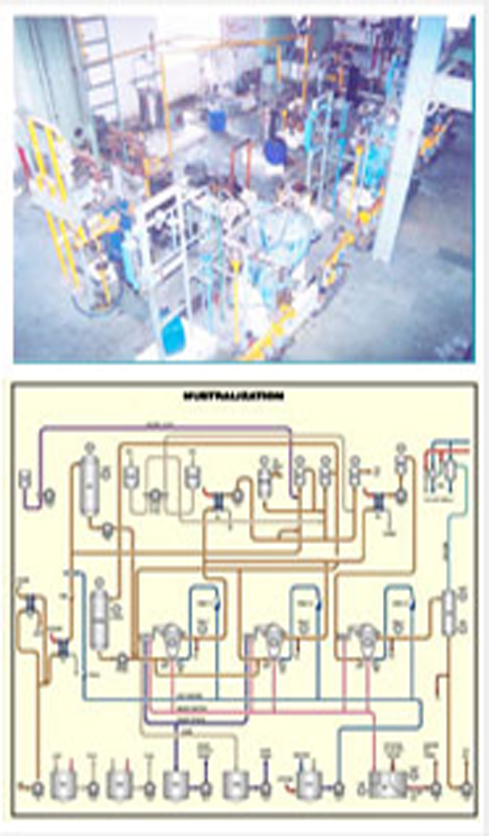

The Degummed Oil is then subject to neutralization with caustic soda where the free fatty Acids are converted into soap and are separated in hermetic separators. The neutralized oil is then washed and dried.

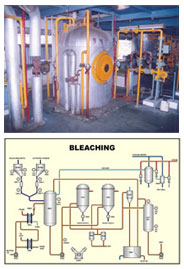

The neutralized Oils are mixed with adequate quantity of bleaching earth dosed through an accurate dosing system.

The mixed Oil is then transferred to a bleacher where Oil under vacuum is agitated with steam. This also imparts the wet bleaching effect.

The Oil is then filtered through pressure leaf filters. The Filter leaves used are in special stainless construction with the mesh imported from reputed suppliers.

The filter have special Pneumatic vibrators for discharge of the cake, and special butterfly valve for easy opening and discharge.

The bleached oil produced has very low phosphorous levels and no soap.

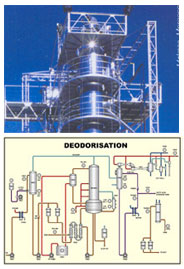

Multistage Deodorisers are in Stainless Steel construction with heating and cooling oil under vacuum. The Deodorisers have special large steam nozzles and mammoth pumps for uniform and aggressive mixing of steam and oil.

Heating arrangement both with thermic fluid heating system or with High Pressure Stream thermosyphon are available. Adequate retention time is provided for light colours. Refined Oils produced have high retention of Tocopherols for stability of Refined oils produced.

Sunflower oil, with a relatively low FFA content is suitable for cold refining or centrifugal dewaxing. In this process, a small amount of acid is added to the crude oil and fed to a hydration tank. After a small retention, required caustic quantity is added into the mixer.

After a small retention, required caustic quantity is added into the mixer. The neutralized oil is then passed through the first centrifugal separator to remove soap.

The neutral oil with small quantity of soap is then chilled in crystallizers for few hours. The wax crystallizes and the oil is then passed through a maturator.

This mixture is now fed to second centrifugal separator where waxes are removed along with soap. The dewaxed neutral is washed in the third centrifugal separator. The oil is then dried and sent to bleaching section.